- Home

- Capability

- Products

- About Us

- Service Industry

- Service Cases

- Video

- Contact Us

-

Language

2025-04-14 15:52:54

These covers are used across various industries due to their durability, lightweight structure, and electrical insulation properties. Common applications include:

Indoor and outdoor electrical installations: Protects junction points and terminal connections from dust, moisture, and accidental contact.

Industrial control panels: Covers for PLC housings and switch enclosures in manufacturing environments.

Consumer electronics: Encasing components in smart home devices, routers, and sensors.

Commercial projects: Used in retail and office buildings for clean, organized electrical enclosures.

The performance of a plastic electrical box cover depends largely on the type of plastic material used. The most widely used materials include:

ABS (Acrylonitrile Butadiene Styrene): Known for impact resistance and ease of machining. Ideal for indoor environments.

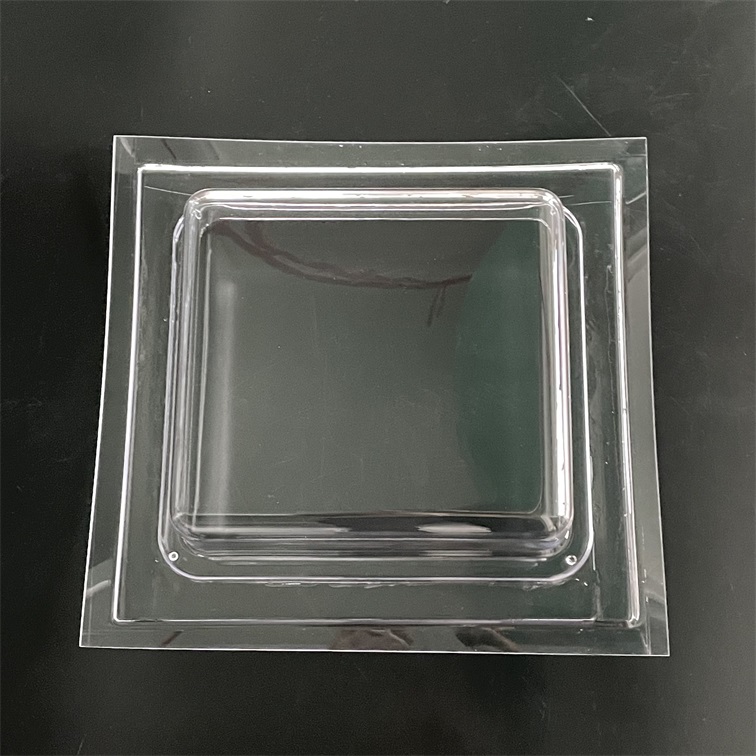

Polycarbonate (PC): Offers superior heat resistance, optical clarity, and flame retardancy. Suitable for demanding applications.

PVC (Polyvinyl Chloride): Cost-effective with good insulation properties, often used in low-voltage installations.

One of the key advantages of plastic electrical box covers is the ability to fully customize them based on application-specific requirements. At Lucky Vacuum Forming, we offer flexible manufacturing processes such as vacuum forming and thermoforming to create precise, durable, and cost-effective covers.

Custom options include:

Size, shape, and thickness adjustments

Pre-cut holes, vents, or slots for cable management

Material selection based on temperature, UV, or chemical resistance

Logo printing, labeling, and surface finish (matte, glossy, textured)

Plastic electrical box covers play a critical role in protecting electrical systems across industries. With customizable features and a wide selection of materials, they can be tailored to meet your specific project needs. To learn more or request a quote, visit the product page here: Plastic Electrical Box Cover.