- Home

- Capability

- Products

- About Us

- Service Industry

- Service Cases

- Video

- Contact Us

-

Language

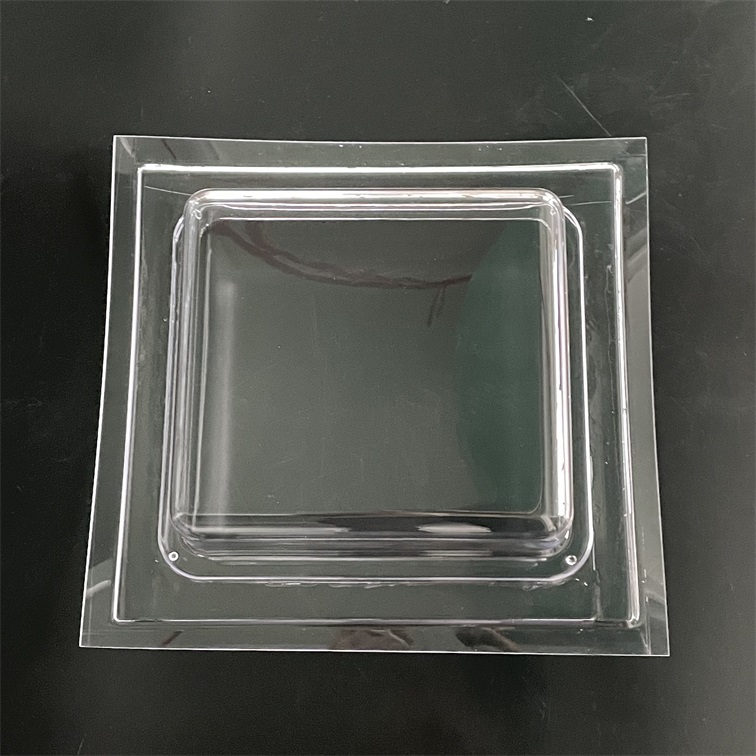

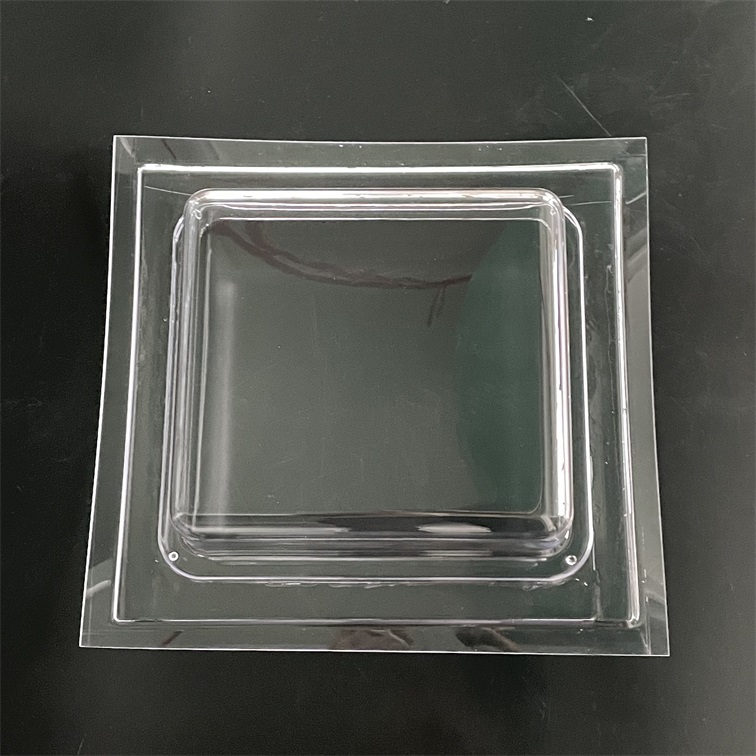

Plastic Electrical Box Cover

Plastic Electrical Box Covers made from polycarbonate (PC) using vacuum thermoforming are widely used in both indoor and outdoor electrical protection systems. Thanks to the high impact strength, transparency, and thermal stability of PC material, these covers are ideal for applications that require both visibility and durability. Common fields include residential wiring, commercial power distribution, industrial control panels, outdoor lighting systems, and renewable energy installations such as solar inverters and battery storage units. The vacuum forming process allows for lightweight, custom-molded designs with precise fitment, making these covers suitable for harsh environments where UV resistance, moisture protection, and insulation performance are critical.

Application

Residential Electrical Systems

Used in homes to cover junction boxes, outlet boxes, and switch boxes, ensuring electrical safety and a clean appearance.

Commercial Buildings

Applied in offices, retail spaces, and public facilities for non-metallic enclosure needs in low-voltage electrical systems.

Industrial Control Panels

Suitable for protecting components in industrial control boxes, machine panels, and instrumentation housings.

Outdoor Electrical Installations

UV-resistant and weatherproof versions are ideal for outdoor junction boxes, lighting systems, and security device enclosures.

Telecom and Networking Cabinets

Used in structured cabling systems and data enclosures to protect sensitive wiring and devices.

Renewable Energy Systems

Applied in solar inverter housings, battery enclosures, and off-grid electrical installations where insulation and corrosion resistance are important.

Marine and RV Electrical Systems

Non-corrosive and moisture-resistant, ideal for boats, caravans, and mobile equipment.

FAQ

Q1: What material is used for these plastic electrical box covers?

Our covers are made from high-quality polycarbonate (PC), known for its excellent impact resistance, UV stability, and flame retardancy. It is suitable for both indoor and outdoor environments.

Q2: What is vacuum thermoforming and how does it benefit the product?

Vacuum thermoforming is a manufacturing process where heated plastic sheets are shaped using a mold and vacuum pressure. This allows for lightweight, custom-fit covers with smooth finishes and consistent thickness, ideal for protective electrical enclosures.

Q3: Are these covers weatherproof or UV-resistant?

Yes, polycarbonate offers natural UV resistance and excellent weatherability, making these covers suitable for outdoor electrical boxes, control panels, and solar systems.

Q4: Can I see through the cover to inspect internal components?

Yes, we offer transparent and translucent options, allowing for easy visual inspection of wiring and status indicators without removing the cover.

Q5: Do you support custom sizes or shapes?

Absolutely. Thanks to the flexibility of vacuum thermoforming, we can produce custom shapes, dimensions, and cutouts based on your specific enclosure design or OEM requirements.

Durable Material: Made from high-quality polycarbonate (PC), known for its impact resistance, UV stability, and flame retardant properties, ensuring long-lasting performance and protection.

Customizable Design: Manufactured using vacuum thermoforming, allowing for custom shapes, sizes, and cutouts to fit specific electrical enclosures and application needs.

Transparency Options: Available in transparent and translucent designs for easy visual inspection of internal components, wiring, and status indicators without needing to remove the cover.

Weatherproof & UV-Resistant: The UV-resistant properties make it ideal for outdoor applications, protecting electrical systems from the sun’s harmful rays, rain, and other weather conditions.

Flame Retardant: Meets UL94 V-0 or V-2 fire resistance standards, making it safe for use in various residential, commercial, and industrial environments.

Lightweight and Cost-Effective: Provides lightweight protection without compromising strength, making it both an economical and durable choice for high-volume installations.

Enhanced Protection: Offers excellent moisture, dust, and impact protection for sensitive electrical components, ensuring safety and reliability.